If you spend time in a woodshop, you’ve probably noticed how fine dust floats around, sticks to tools, and maybe even irritates your lungs. Having a good air filtration system isn’t just about cleanup—it’s about health, comfort, and protecting your finish work.

In 2025 the best systems are more refined: high CFM (cubic feet per minute) airflow, low noise so you can talk while the unit runs, filters that trap really fine wood dust (down to 1 micron or less), and mounting/installation that works for your space. We’ll walk through what matters, how to decide, then examine some strong system choices—with pros and cons—so you can pick what fits your workshop.

Why Shop Air Filtration Systems Matter

Woodworking produces two kinds of dust: large chips that fall quickly, and very fine airborne particles (often < 5 microns) that linger, get into your lungs, mess up your finishes, and settle on everything. A good filtration system keeps the air moving regularly (so dust doesn't constantly sit), traps these fine particles in high-quality filters, and runs quietly enough that you don’t turn it off because it’s too noisy.

A testing review in WOOD Magazine found that a top system cleared the air faster and more thoroughly than box-fans or makeshift filters.

So better airflow + better filter media + good layout = better air, better working conditions.

What to Look For: CFM, Noise & Filter Type

CFM (Airflow)

The higher the CFM, the more air the unit moves and the faster it clears/filters your space. In a large shop you might want 1,000+ CFM; in a smaller hobby garage maybe 500-700 CFM is fine. The WOOD Magazine test wrote: “Jet AFS-2000 … top airflow … large filters” for best overall.

Noise Level

A system that sounds like a jet engine will annoy you and maybe get turned off. Some spec sheets list decibels at 300mm distance (e.g., ~60-70 dB). One example: the “Dust Right Full-Size Air Filtration Unit” has noise ~66 dB @550 CFM.

Filter Type & Efficiency

Look for a two-stage or multi-stage filter: an outer prefilter for larger particles (e.g., 5 microns), then an inner finer filter (1 micron or better). The material and filter area matter: smaller filters increase resistance and reduce airflow. As one forum user noted: “Adding a second MERV13 filter to the outflow of the Jet1000B… actually made things worse.”

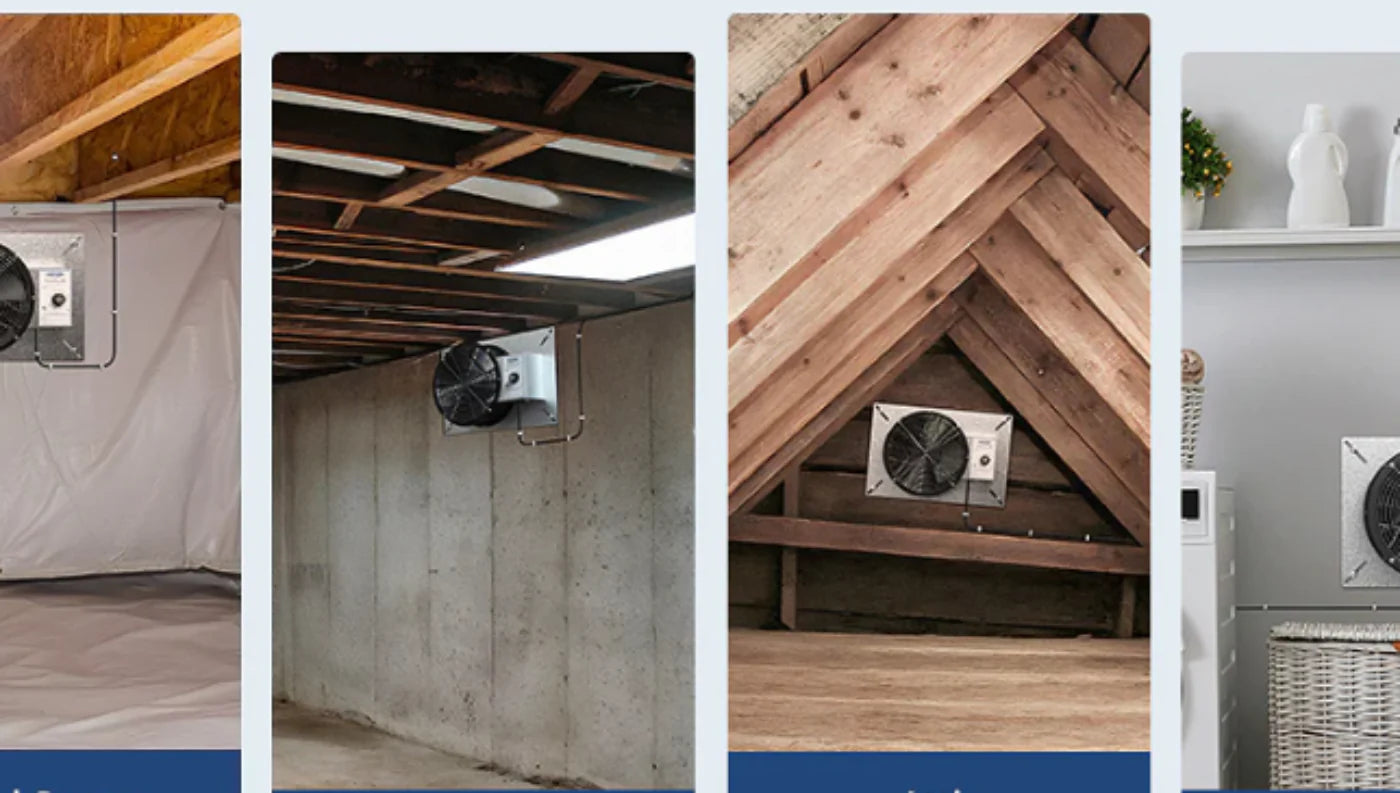

Mounting / Layout

Ceiling-mounted units save floor space and circulate from above; wall or floor units may be easier to install. Consider that the unit should help move air across the workspace—not just sit in one corner. Also consider ease of filter replacement, maintenance access, and timer or scheduling capability.

Top System Choices (2025 Edition)

Here are several good air filtration systems for woodshops, covering different sizes and budgets. For each we’ll note description, advantages & disadvantages.

AlorAir Purecare 1050IG

This is an industrial/workshop air filtration system by AlorAir designed for woodshop/garage use. Specs list up to ~1,050 CFM from a “Powered Vortex Fan” for around ~1,100 sq ft.

Advantages:

- High airflow ~1,050 CFM, good for larger shop spaces.

- Built for workshop use (metal construction, dual-speed).

- Good for serious dust loads.

Disadvantages:

- Larger physical size; may require mounting overhead or good clearance.

- Probably more expensive.

-

Might be over-capacity for small hobby space (could run quietly but you’ll pay more).

AlorAir Purecare 780S

A smaller unit from the same line, rated for about up to ~800 sq ft with airflow ~580/780 CFM two-speed.

Advantages:

- More reasonable size for moderate-sized workshop or garage.

- Lower footprint, easier install.

- Balanced value.

Disadvantages:

- Less airflow than the big model; if you have a large space or heavy dust load you may wish it were bigger.

- Might still be more than you need for a very small garage.

Dust Right Full-Size Air Filtration Unit (Rockler)

Ceiling-mounted unit with up to 1,100 CFM (three speeds: 550/700/1,100). Includes remote and timer.

Advantages:

- Good airflow for size; remote control & timer very handy.

- Specific noise ratings given (~66-73 dB depending on speed) offer realistic expectations.

- Strong value for moderate shop sizes.

Disadvantages:

- Filter media may not be as high grade as industrial units (check micron rating).

-

Might not have as high capacity or long-term durability as pro units.

Higher speeds may generate noise or draft.

How to Choose the Right Size for Your Shop

- Estimate your shop volume (length × width × height).

- Decide how many “air changes per hour” you want (typically 8–12 for heavy dust loads).

- Choose a system whose CFM supports that airflow. For example: a shop 20’ × 30’ × 9’ = 5,400 cu ft. To get 8 air-changes/hour: 5,400 × 8 = 43,200 cu ft/hour → divide by 60 = ~720 CFM. So a system rated ~800 CFM is sensible.

- Match filter type (micron rating) based on dust severity—if you do a lot of sanding or turning, aim for sub-micron inner filter.

- Check mounting & noise: overhead may reduce footprint and increase circulation, but ensure you can service filter and unit.

- Budget & maintainability: filters cost money and must be replaced or cleaned; higher capacity units mean more cost.

Maintenance & Best Practices

- Run after work: Let the unit continue for 30–60 minutes after you finish, so airborne fine dust settles and gets filtered.

- Clean/replace filters regularly: When airflow drops or you feel less air movement, check filters. Clogged filters reduce CFM and reduce performance dramatically.

- Position for airflow: Try to place the unit where it creates circulation across the room—not just into a corner. Ceiling mounting often works well.

- Supplement with source dust collection: Even the best air filtration does not replace hooking your tools to proper dust extraction. The filtration system is for the mist and fine particles that escape.

- Consider noise and timer: Use timer features so you don’t forget it running overnight or turn it off because it’s loud.

- Monitor and upgrade filters: Some users found significant improvement when upgrading their filter to a higher MERV/pocket filter.

Frequently Asked Questions

What size air filtration system do I need for my woodshop?

Estimate your shop’s cubic-foot volume and aim for roughly 8–12 air changes per hour. Then pick a system whose CFM rating supports that. For many hobby garages (~400–800 sq ft), a 500-800 CFM unit is sufficient. Larger shops (>1,000 sq ft) should consider 1,000 CFM+ units.

How important is filter micron rating?

Very important. Fine dust (less than 5 microns) stays airborne and is harder to remove. A good system uses a two-stage filter (outer ~5-microns, inner ~1-micron or lower). Smaller micron ratings mean better capture but often higher airflow resistance, so balance filter rating and airflow rate.

Will a ceiling-mounted unit work better than floor?

Yes, often. Ceiling mounting helps pull dust from above tools and keep circulation across the space. It also keeps the unit out of the way. But you must ensure the unit is supported properly, filter access is easy, and you have enough clearance.

What noise level is acceptable?

Noise around 60-70 dB while running is fairly reasonable for a woodshop. If it’s much louder you might avoid running it long. As an example, one unit is rated ~66 dB at 550 CFM speed.

Is air filtration enough or do I also need dust collection?

Air filtration systems filter airborne fine dust after it’s been generated. Dust collection systems attach to tools and remove chips and dust at the source (before it escapes). You ideally need both: source collection plus ambient air filtration for the particles that escape.

Conclusion

If you’re serious about your woodshop’s air quality, the best air filtration system in 2025 is one that offers strong airflow (CFM), quiet enough to run in the background, and a filter set-up capable of capturing fine dust. For most hobby spaces consider something in the 500-800 CFM range; for larger or heavy-use shops go toward 1,000 CFM+.

Among the solid choices we highlighted, the AlorAir Purecare 1050IG offers high performance for large workshops, the Purecare 780S fits moderate sized shops, and the Dust Right Full-Size Air Filtration Unit gives good value for many users.